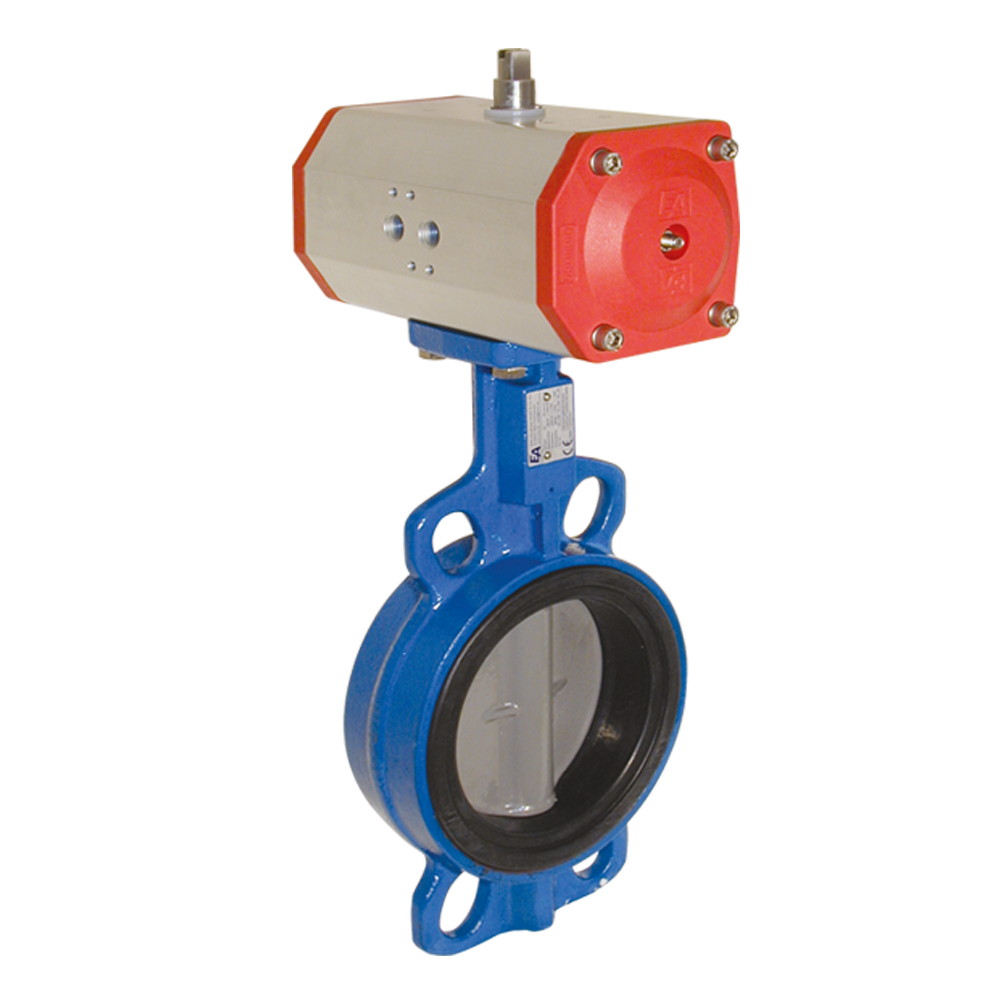

Butterfly valves

High-quality butterfly valves from END-Armaturen in wafer and lug design with bodies made of stainless steel, cast iron or aluminium.

Examples:

✓ High Delivery Performance ✓ Tested Quality ✓ Competent Advisors

Cart

Creating an account has many advantages: quick and comfortable ordering, saving more than one address, tracking orders and much more.